Dimensional Mastery: Unveiling 4D Printing Innovations

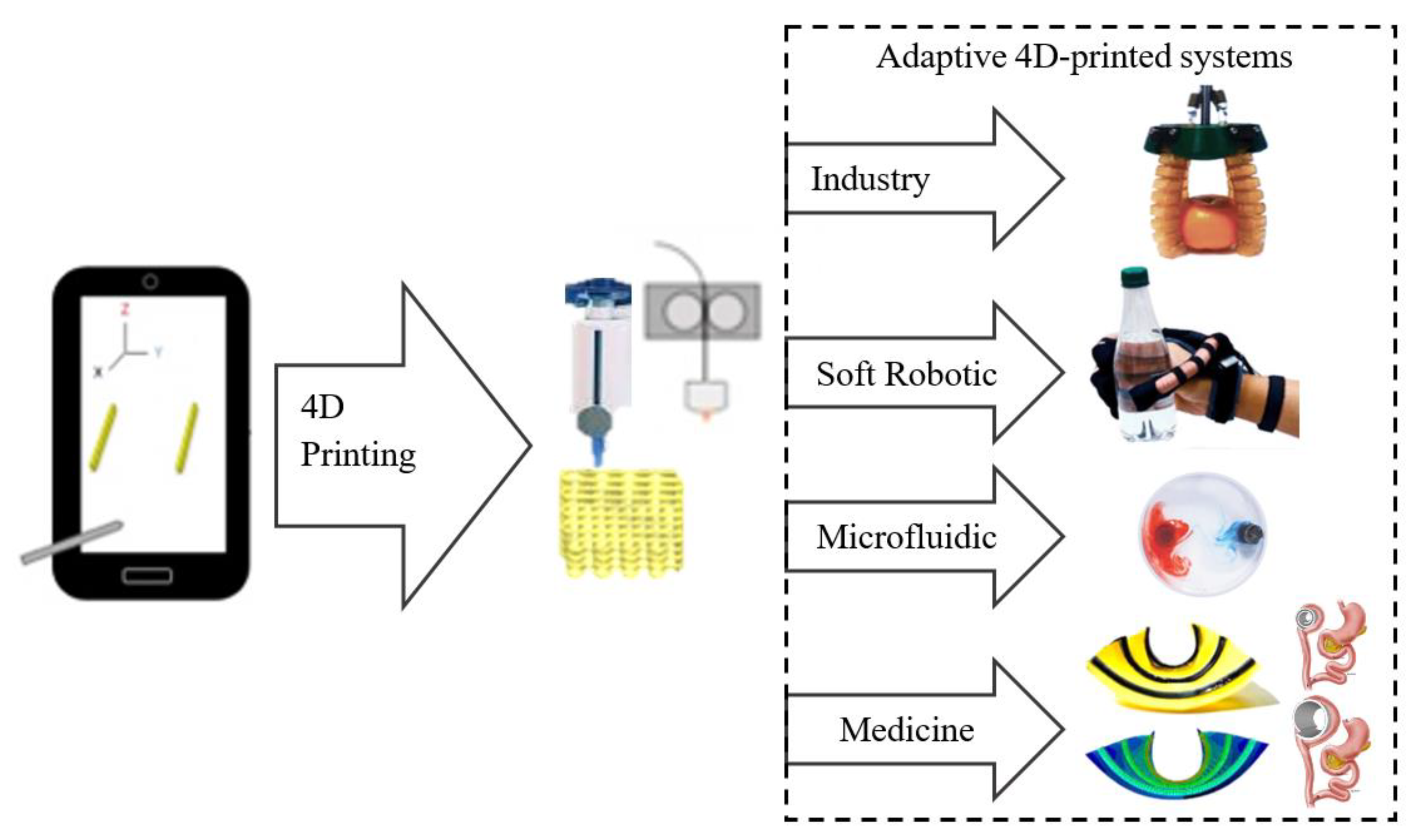

In the realm of advanced manufacturing, 4D printing emerges as a groundbreaking technology that goes beyond the boundaries of traditional 3D printing. This article explores the exciting advancements in 4D printing, delving into the transformative possibilities it brings to various industries.

Understanding 4D Printing: Adding the Dimension of Time

At its core, 4D printing is an extension of 3D printing with an additional dimension: time. The term “4D” refers to the ability of printed objects to transform or change their shape over time in response to external stimuli, such as temperature, humidity, or light. This dynamic aspect opens up a new realm of possibilities for creating adaptive and responsive structures.

Smart Materials in 4D Printing: Shape-Shifting Wonders

The magic of 4D printing lies in the use of smart materials known as programmable or shape-memory materials. These materials have the ability to change their form when subjected to specific conditions. In the context of 4D printing, these materials are precisely incorporated into the printing process, allowing the final object to exhibit controlled shape-shifting behavior.

Applications in Aerospace: Deployable Structures and Morphing Wings

One of the key sectors benefiting from 4D printing advancements is aerospace. The ability to create deployable structures and morphing wings presents opportunities for lightweight, adaptive components. Imagine an aircraft wing that adjusts its shape during flight to optimize aerodynamics, improving fuel efficiency and overall performance.

Biomedical Innovations: Self-Folding Medical Devices

In the biomedical field, 4D printing opens avenues for creating self-folding medical devices. These devices can be designed to change shape or size in response to the body’s internal conditions. For example, stents that can adapt to blood vessels’ changing dimensions or drug delivery systems with the ability to respond to specific biological cues.

Construction and Infrastructure: Adaptive Building Components

In the realm of construction and infrastructure, 4D printing introduces the concept of adaptive building components. Imagine structures that can respond to environmental changes, such as buildings with facades that open and close based on sunlight or temperature variations. This dynamic architecture not only adds an aesthetic dimension but also enhances energy efficiency.

Consumer Products: Customizable and Responsive Designs

4D printing brings a new level of customization to consumer products. From clothing that adjusts to body movements to footwear that adapts to the terrain, the ability to create responsive and customizable designs enhances user experience. The fashion and consumer goods industries are exploring innovative applications that marry form and function.

Environmental Sustainability: Smart Materials for Resource Efficiency

The use of smart materials in 4D printing aligns with the principles of environmental sustainability. The adaptability of objects created through 4D printing can contribute to resource efficiency. For instance, structures that respond to weather conditions can optimize energy usage, promoting a more sustainable approach to design and manufacturing.

Challenges and Future Prospects: From Design Complexity to Scalability

While 4D printing holds immense promise, it comes with challenges. Designing complex structures that respond reliably to external stimuli requires advanced computational modeling and material science. Additionally, scalability and cost-effectiveness remain considerations for widespread adoption. However, ongoing research and technological advancements are addressing these challenges, paving the way for a future where 4D printing becomes more accessible.

Exploring 4D Printing Advancements

Stay updated on the latest advancements in 4D printing by visiting 4D Printing Advancements. This resource provides insights into cutting-edge research, applications across industries, and the evolving landscape of 4D printing, shaping the future of additive manufacturing.

In conclusion, 4D printing represents a paradigm shift in additive manufacturing, introducing a dynamic element that extends beyond the confines of static 3D-printed objects. From aerospace to healthcare, the transformative potential of 4D printing is reshaping industries, offering solutions that adapt and evolve in response to the changing needs of our complex world.